Anti-Foam Control Solutions-- High-Performance Anti-Foam Products for Several Industries

Anti-Foam Control Solutions-- High-Performance Anti-Foam Products for Several Industries

Blog Article

Finest Practices for Selecting the Right Anti-Foam Control Service for Your Demands

Picking an efficient anti-foam control service necessitates a comprehensive evaluation of your one-of-a-kind functional requirements. Key factors to consider include the particular residential properties of your procedure, such as ph, chemical, and temperature interactions, all of which substantially affect the efficiency of defoaming representatives.

Understand Your Foam Issue

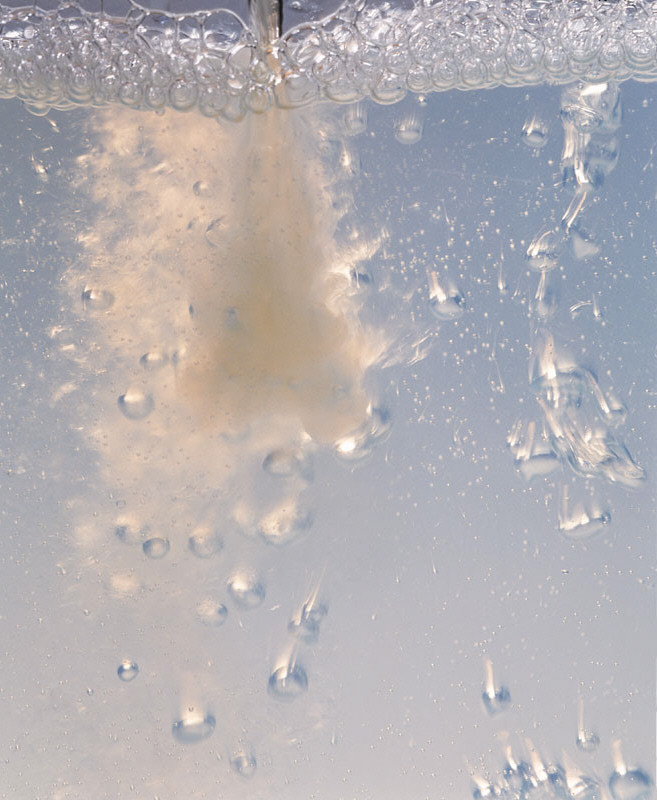

Often, companies come across foam-related concerns that can impede operational effectiveness and product high quality. Foam formation can occur during different procedures, including mixing, fermenting, and transportation, and it typically brings about tools ineffectiveness, production downtime, and raised functional costs. Comprehending the underlying sources of foam generation is critical for addressing the issue successfully.

Foam can occur from a number of aspects, such as the nature of the materials involved, anxiety degrees, temperature variants, and chain reactions. As an example, particular surfactants can intensify lathering, while high shear mixing can introduce air, leading to unwanted foam accumulation. In addition, ecological conditions and the specific features of the liquid systems in operation can substantially influence foam behavior.

Identifying the kind of foam-- whether it is unstable or stable-- is likewise crucial. Secure foam has a tendency to linger longer and is more challenging to manage, while unstable foam might dissipate a lot more quickly. Anti-Foam Control Solutions. By assessing these variables, organizations can get understandings right into their foam issues, enabling them to create targeted methods to reduce foam formation and boost general procedure performance. This fundamental understanding is important for selecting a suitable anti-foam control service customized to particular operational demands.

Assess Anti-Foam Options

When thinking about anti-foam alternatives, it is important to thoroughly evaluate the various solutions offered on the market to discover one of the most appropriate service for your details foam-related challenges. Anti-foam representatives come in diverse kinds, including silicone-based, non-silicone, and all-natural solutions, each offering distinctive properties and efficiency qualities.

Begin by assessing the certain application requirements, such as temperature level limits, pH levels, and the kind of foam being generated. For circumstances, silicone-based representatives are known for their performance in high-temperature atmospheres, while non-silicone alternatives might be more suitable in food processing applications as a result of governing considerations.

It is additionally important to think about the rate of application and the wanted long life of the foam control. Some solutions may offer prompt defoaming activity, while others use extended stability. Conducting small-scale examinations can give understandings into the performance of each option in real-world problems.

Consider Application Compatibility

In the realm of anti-foam options, making certain application compatibility is paramount for attaining optimal performance. The efficiency of an anti-foam agent mostly depends on its capability to work harmoniously within the certain criteria of your application, including temperature level, pH, and the visibility of other chemicals. Various formulas might do variably across varied conditions, hence complete testing is crucial.

Begin by determining the qualities of your process, such as viscosity and the nature of the medium in which the anti-foam will be utilized. As an Read More Here example, some anti-foam agents may function well in liquid services yet fall short in natural solvents. Furthermore, take into consideration the possible interactions with existing ingredients and products to stay clear of unfavorable effects.

It is also important you could try here to review the approach of application. Whether the anti-foam is introduced continuously or batch-wise can influence its efficacy and long life in the system. Make certain that the selected product is not just compatible with the functional specifications but additionally straightens with any kind of regulative needs pertinent to your sector.

Assess Environmental Effect

Exactly how does the environmental impact of an anti-foam control service influence your total selection process? The ecological impact of your picked anti-foam representative is extremely important, as it shows your commitment to sustainability and governing compliance. Selecting a product with minimal environmental consequences can improve your company image and foster client count on.

When analyzing environmental effect, consider the biodegradability of the anti-foam solution. Biodegradable alternatives are typically preferable, as they break down much more rapidly and decrease lasting environmental injury. Additionally, assess the potential for bioaccumulation and toxicity to marine life. Solutions with high poisoning can pose considerable dangers to local ecosystems, potentially leading to governing penalties and environmental destruction.

Another essential factor is the existence of unsafe substances. Anti-foams consisting of harmful chemicals may demand special delivery and disposal actions, why not try this out boosting functional prices and making complex compliance with ecological laws. For that reason, choosing environment-friendly alternatives can mitigate these risks.

Display and Enhance Performance

To make best use of the performance of your anti-foam control remedy, it is important to frequently monitor and enhance its performance. Continuous assessment permits the identification of any kind of inconsistencies in foam levels and the subsequent performance of the anti-foam agent.

Apply a methodical approach to monitor crucial efficiency indications (KPIs), such as foam volume, security, and the response time of the anti-foam representative. Use analytical devices and strategies, such as aesthetic evaluations, foam height measurements, and specialized sensing units, to collect exact data.

Additionally, preserve open interaction with suppliers for technical support and understandings on the most up to date improvements in anti-foam modern technology. This aggressive approach not only help in attaining ideal efficiency but also minimizes functional disturbances and enhances total procedure efficiency. Frequently reviewing and refining your anti-foam method ensures that you are successfully handling foam-related challenges, ultimately bring about improved performance and price savings.

Final Thought

To conclude, picking the ideal anti-foam control remedy requires an extensive assessment of specific application demands, consisting of temperature level, pH degrees, and chemical compatibility. Strenuous testing for prompt and prolonged defoaming efficiency is vital, as is consideration of ecological impacts and regulatory conformity. By prioritizing eco-friendly options and constantly checking performance, functional performance can be enhanced while successfully minimizing foam-related challenges. Abiding by these ideal methods will help with informed decision-making in anti-foam control remedies.

Selecting an efficient anti-foam control option demands a comprehensive examination of your special functional demands.In the realm of anti-foam options, guaranteeing application compatibility is critical for attaining optimal performance.Exactly how does the ecological impact of an anti-foam control solution influence your general selection procedure?In final thought, choosing the proper anti-foam control solution necessitates an extensive analysis of certain application needs, consisting of temperature, pH levels, and chemical compatibility (Anti-Foam Control Solutions). Adhering to these best practices will certainly facilitate enlightened decision-making in anti-foam control remedies

Report this page